- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Customized furniture drilling auto tool changer router CNC cutting machine with boring head. Equipped with world famous brand parts, guarantee the working effect and the life of the machine....

| Availability: | |

|---|---|

| Quantity: | |

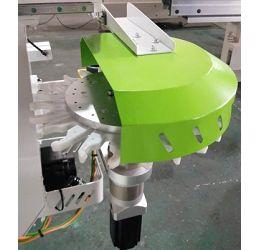

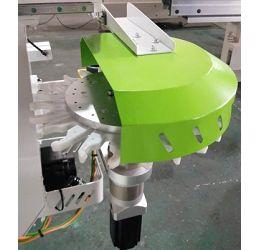

Customized furniture drilling auto tool changer router CNC cutting machine with boring head. Equipped with world famous brand parts, guarantee the working effect and the life of the machine. Auto loading and unloading system, saving the working time and workers.12 tools for changing, meet all kinds carving, cutting and engraving work, 5+4 vertical boring head meet the drillings need.

Many optional parts can be chosen.

Perfect for customized cabinet and furniture making, Adapt to the modern trend...

Application:

Woodworking: three-dimensional wave board processing, cabinet doors, solid wood doors, wooden craft, paint doors, screens, craft fan window processing, shoe polisher, game cabinets and panels, mahjong table, computer desk and furniture products, auxiliary processing .

Performance features:

1.Industrial heavy-duty steel lathe bed.

2. High precision square rail from Taiwan.

3. Famous brand servo motors and drivers.

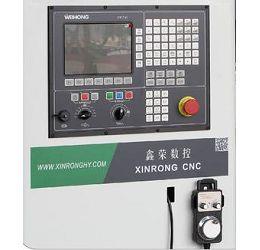

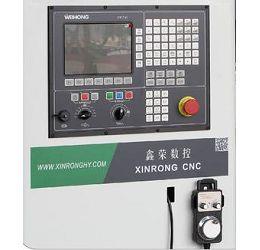

4. Professional WEIHONG Control system, easy to operate.

5. ATC spindle with linear type auto-tool changer of 8 tools.

6. The traveling speed can reach 50m/min, the cutting speed can reach 15-20m/min

7. CE certificate

Technical specifications:

X-Y-Z axis working area: 1300*2500*160mm

Machine size: 3600*2200*2150mm

Working size: 1260*2440mm

Max. travelling speed: 50m/min.

Proceeding speed: 15-20m/min.

Main spindle speed: 18000r/min.

Main spindle motor power: 6kw

Vacuum pump motor power: 7.5kw water cooling

Packaging & Delivery

packing details: Protective Film, etc. optional: plywood box by LCL

delivery time: normally we can guarantee in 15 days after receiving down payment

Warranty: We guarantee the machine with one-year warranty

Installation: normally we request factory should send one staff to be trained in our factory, which is more convenient for understanding and can solve all problems here. But If needed, we can send our engineers for the installation and operation training of our machines.

After sale service:

1. Technical support by phone, email or whatsap /wechat

2. Friendly English version manual and operation video CD disk.

3. Engineer available to service machinery overseas if required

Customized furniture drilling auto tool changer router CNC cutting machine with boring head. Equipped with world famous brand parts, guarantee the working effect and the life of the machine. Auto loading and unloading system, saving the working time and workers.12 tools for changing, meet all kinds carving, cutting and engraving work, 5+4 vertical boring head meet the drillings need.

Many optional parts can be chosen.

Perfect for customized cabinet and furniture making, Adapt to the modern trend...

Application:

Woodworking: three-dimensional wave board processing, cabinet doors, solid wood doors, wooden craft, paint doors, screens, craft fan window processing, shoe polisher, game cabinets and panels, mahjong table, computer desk and furniture products, auxiliary processing .

Performance features:

1.Industrial heavy-duty steel lathe bed.

2. High precision square rail from Taiwan.

3. Famous brand servo motors and drivers.

4. Professional WEIHONG Control system, easy to operate.

5. ATC spindle with linear type auto-tool changer of 8 tools.

6. The traveling speed can reach 50m/min, the cutting speed can reach 15-20m/min

7. CE certificate

Technical specifications:

X-Y-Z axis working area: 1300*2500*160mm

Machine size: 3600*2200*2150mm

Working size: 1260*2440mm

Max. travelling speed: 50m/min.

Proceeding speed: 15-20m/min.

Main spindle speed: 18000r/min.

Main spindle motor power: 6kw

Vacuum pump motor power: 7.5kw water cooling

Packaging & Delivery

packing details: Protective Film, etc. optional: plywood box by LCL

delivery time: normally we can guarantee in 15 days after receiving down payment

Warranty: We guarantee the machine with one-year warranty

Installation: normally we request factory should send one staff to be trained in our factory, which is more convenient for understanding and can solve all problems here. But If needed, we can send our engineers for the installation and operation training of our machines.

After sale service:

1. Technical support by phone, email or whatsap /wechat

2. Friendly English version manual and operation video CD disk.

3. Engineer available to service machinery overseas if required