- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Laminate hot press is fit for the furniture factory or panel secondary processing plant, which can make lamination for furniture panel, building partition, wooden door or laminate all kinds of decorative material on man-made board....

| Availability: | |

|---|---|

| Quantity: | |

Laminate hot press is fit for the furniture factory or panel secondary processing plant, which can make lamination for furniture panel, building partition, wooden door or laminate all kinds of decorative material on man-made board. It also can be used for drying or leveling veneer.

Performance features:

1. Adopt solid drilled conduction board, warming up faster, uniform thermal conductivity, and energy consumption lower.

2. Omron or Schneider main electric components, it is stable and durable.

3. Hawe valve from German for auto-open hydraulic valve, high holding pressure, reliable performance, less human factors.

4. Piston mode for cylinder. Grind, plate hard chromium on the surface and polish piston after heat treatment. It is durable and high precision.

5. Adopt special seal-rings for reliability and durability.

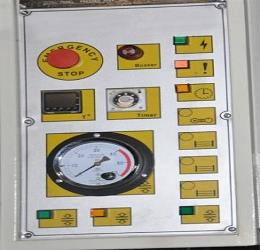

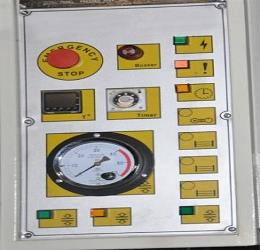

6. Configure pull E-stop switch, temperature secondary protection equipment.

Technical specifications:

Total pressure: 1200KN

Working layers: 3 layers

Unit area pressure: 3.7kgf/cm2

Platen no.: 4 nos.

Platen size: 2500*1300*42mm

Opening: 120mm

Cylinder no.: 8 nos.

Cylinder diameter: 85mm

Heating way: electric heated with thermal oil

Platen opening way: automatically

Total motor power: 52.75kw

Closed speed: 40mm/s

Packaging & Delivery

packing details: Protective Film, etc. optional: plywood box by LCL

delivery time: normally we can guarantee in 15 days after receiving down payment

Installation: normally we request factory should send one staff to be trained in our factory, which is more convenient for understanding and can solve all problems here. But If needed, we can send our engineers for the installation and operation training of our machines

Warranty & After sale service:

1. We have 12 months warranty for the whole machine.

2. We can supply technical support by phone, email or WhatsApp on line

3. Friendly English version manual and operation video CD disk.

Laminate hot press is fit for the furniture factory or panel secondary processing plant, which can make lamination for furniture panel, building partition, wooden door or laminate all kinds of decorative material on man-made board. It also can be used for drying or leveling veneer.

Performance features:

1. Adopt solid drilled conduction board, warming up faster, uniform thermal conductivity, and energy consumption lower.

2. Omron or Schneider main electric components, it is stable and durable.

3. Hawe valve from German for auto-open hydraulic valve, high holding pressure, reliable performance, less human factors.

4. Piston mode for cylinder. Grind, plate hard chromium on the surface and polish piston after heat treatment. It is durable and high precision.

5. Adopt special seal-rings for reliability and durability.

6. Configure pull E-stop switch, temperature secondary protection equipment.

Technical specifications:

Total pressure: 1200KN

Working layers: 3 layers

Unit area pressure: 3.7kgf/cm2

Platen no.: 4 nos.

Platen size: 2500*1300*42mm

Opening: 120mm

Cylinder no.: 8 nos.

Cylinder diameter: 85mm

Heating way: electric heated with thermal oil

Platen opening way: automatically

Total motor power: 52.75kw

Closed speed: 40mm/s

Packaging & Delivery

packing details: Protective Film, etc. optional: plywood box by LCL

delivery time: normally we can guarantee in 15 days after receiving down payment

Installation: normally we request factory should send one staff to be trained in our factory, which is more convenient for understanding and can solve all problems here. But If needed, we can send our engineers for the installation and operation training of our machines

Warranty & After sale service:

1. We have 12 months warranty for the whole machine.

2. We can supply technical support by phone, email or WhatsApp on line

3. Friendly English version manual and operation video CD disk.