- All

- Product Name

- Product Keyword

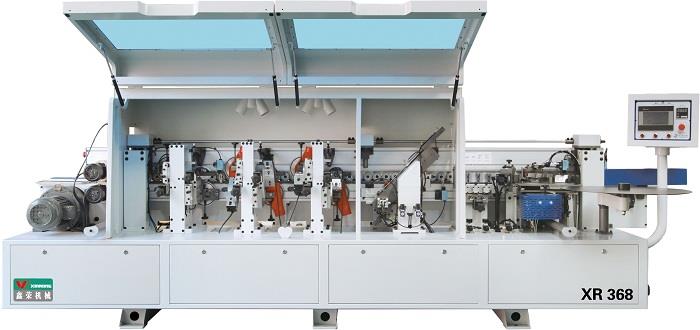

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1 Author: Site Editor Publish Time: 2020-10-29 Origin: Site

Precautions

The main advantages of the curved and straight edge banding machine are firm bonding, fast, light, and high efficiency. In order to achieve this effect, in addition to buying a good edge banding machine, we must also pay attention to the edge banding tape, hot melt adhesive, substrate, Factors such as working environment and operating methods. When choosing edge banding, attention should be paid to factors such as width, thickness, material, toughness, and degree of surface treatment. For hot melt adhesives, pay attention to the difference between high, medium and low temperature adhesives to match the type of edge banding, and scientifically set the heating control temperature and the flowability and solidification delay of the sol. The selection of the base material also has quality, temperature, parallelism and perpendicularity requirements of the section. The indoor temperature and dust concentration of the working environment also need to be considered. The base material, edge banding tape, and rubber shaft running speed, pressure, balance, etc. Coherence, etc. will affect the edge banding effect. Four, the method of repairing the curved straight edge banding machine The curved straight edge banding machine will also have some problems and failures in use, the common failures are:

1. Electrical failure. Including host stoppage, slow heating up, program disorder, etc., if it is not eliminated in time, it will burn out the motor and heating tube, or even damage the entire mechanical system. Mainly check the electrical control box, motor, heating tube, delayer, etc. during maintenance. This type of overhaul is generally repaired by professionals or by the manufacturer.

2. Air circuit failure. Including air valve failure, air leakage, low air pressure, cutting knife, feeding material not working, etc., mainly check the integrity of various pneumatic components, replacement parts can be carried out under the guidance of the manufacturer's technicians.

3. Mechanical failure. Mainly include transmission failure, uneven glue application, feeding failure and cutter failure, etc. Mainly check the integrity and firm parts of each mechanical part, and whether the transmission part is offset.

4. Bonding failure. Such as failure to stick, deviation, entrainment, etc., this is a comprehensive failure related to the rubber shaft, edge banding, sol, substrate and operation. Such failures may occur alternately or singly, and the specific maintenance depends on the situation.